Test Development Services

IMPROVE RELIABILITY AND PERFORMANCE WITH SMART TEST DESIGN.

TEST DESIGN HAS A DIRECT IMPACT ON PRODUCT COST AND DELIVERY, AND PLAYS A CRITICAL ROLE IN A PRODUCT’S ULTIMATE SUCCESS. AND YET, FOR SOME OEMS, TEST IS AN AFTERTHOUGHT.

Today’s competitive environment requires OEMs to launch products quickly but without compromising quality.

There’s nothing worse than dissatisfied customers, or having to justify the cost of rework, or causing a customer downtime due to preventable failures.

If you haven’t invested in expert test design, you’re taking a huge risk.

Creation Technologies Can Help You Leverage Test Design, Development and Execution to Commercialize a Successful Product and Extend Its Profitability.

Learn How After Market Services Can Benefit Your Business.

“Proactive Solutions for Your Customers

Aftermarket Division of Industrial Controls OEM

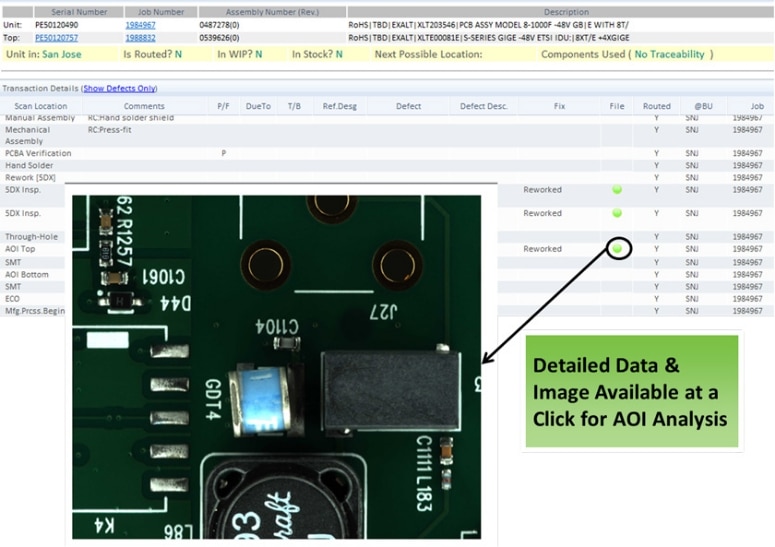

DEMONSTRATE IMPROVEMENTS IN PRODUCT RELIABILITY WITH DETAILED DFT REPORTING AND REAL-TIME DATA IN OUR VISION CUSTOMER PORTAL.

Creation Technologies makes it easy for quality and test engineers to understand key test strategy drivers and results within a volume production environment.

Real-time information through Vision Customer Portal, including:

- Detailed inspection and test failure data, including location, failure analysis and resolution

- WIP reporting, including status, FPTY and defects

- AOI defect data with images of defects

Trend analysis

DFT Guidelines for risk analysis

- Critical issues and suggested solutions

- Engineering guidelines for PCB design

Customized DFT reporting based on your requirements:

- Probe selection and placement, boundary scan analysis, bed-of-nails fixture design

- Detailed testability reports

- Failure analysis and reliability

DEMONSTRATE IMPROVEMENTS IN PRODUCT RELIABILITY WITH DETAILED DFT REPORTING AND REAL-TIME DATA IN OUR VISION CUSTOMER PORTAL.

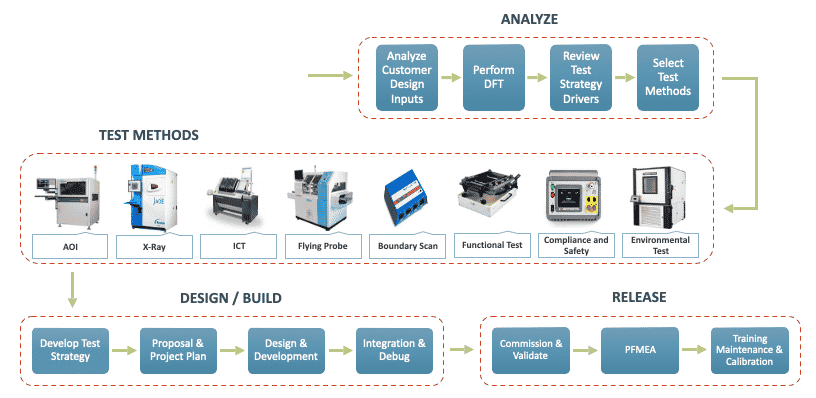

Creation has advanced mechanical and electrical test and inspection capabilities for complex integrated systems as well as circuit board assemblies.

ICT and MDA, automatic optical inspection (AOI), boundary scan, 5DX

Rapid development, fixtureless and flying probe test

Device programming, software customization and configuration

System and sub-system in-line and offline functional test through final test

Complex electro-mechanical and RF test expertise

Burn-in, high-voltage test, electrical safety test

Environmental stress screening and verification, HASS, HALT

Build-to-order and configure-to-order services

IMPROVE YOUR PRODUCT’S TESTABILITY AND ENSURE QUALITY BY WORKING WITH CREATION’S IN-HOUSE TEST ENGINEERING EXPERTS.

At any phase in the design and development process, or as part of our electronics manufacturing services, test engineering teams in your business units of choice will work with you to develop a test strategy and select test methods that enable you to reduce inventory bone-piles, increase yields and accelerate time-to-volume for every product we build.

Creation has advanced mechanical and electrical test and inspection capabilities for complex integrated systems as well as circuit board assemblies.

– Turnkey product development with emphasis on test design and development, including initial system risk analysis, design validation and verification, and agency safety testing

– Expert implementation of your existing test strategy, or development of a new test plan

– Comprehensive test strategy development in every – Creation business unit around the world

– Dedicated test engineers working as part of your Customer-Focused Team, driving DFT activities with expert support for engineering changes

– Proven software and proprietary guidelines guarantee a standardized approach

– In-house test fixture design and development

ANALYSIS AND TESTING LABORATORY

Creation now offers a complete suite of analysis, testing and failure diagnostic services all in-house, facilitating our ability to validate subassembly performance for your life-saving and other mission-critical products.