Quality and Continuous Improvement

Creation's Commitment to Quality

Creation manufactures and designs to all major standards.

Quality Certifications & Regulatory Expertise

UL, CSA, TUV, CE, FDA, FM, MET, ETL, IEC, IECEx, JPAL

IPC RoHS Compliance Certification and RoHS Exemption Management

FDA-Registered Business Units

International Traffic in Arms (ITAR) Registration

Canadian Controlled Goods Directorate (CGD) Registration

Customs Trade Partnership Against Terrorism (C-TPAT) Registration

Business Systems Validated for ITAR and CGD

Customer & Government Source Inspections

AS9100D Roadmap, FAA NAS Requirements

IPC-A-610 and IPC-J-STD-001, Class 2 and Class 3

MIL-STD-810F, IPC/WHMA-A-620 & MIL-STD Wiring and MIL-DTL-3100

Familiarity with Offset Credits & Programs

Customer Benefits of Creation’s Continuous Improvement

Creation has a unique and potent combination in the EMS industry. We identify and add value for our OEM customers. Continuously.

Improved Cash Flow

Scale rapidly. Some of Creation’s customers have improved inventory turns and reduced carrying costs by as much as 65%, by working with us to establish a lean production program that makes sense.

Fewer Customer Returns

See your field failures cut in half. Combine Creation’s ISO 9001:2015, ISO 13485:2016 and ISO 14001:2015-certified facilities with expert in-house test engineering resources for continual improvement to product quality and reliability.

Improved Productivity

Reduce administrative burdens like managing suppliers. Limit time spent rescheduling deliveries to just minutes a day, and get all the visibility you need through Creation’s Customer Portal.

Satisfied Customers

Improve your on-time shipments to your customers with Creation’s responsive team and process, and options for direct order fulfillment. One of Creation’s customers improved their OTS from 80% to 98.4%.

Less Exposure

Creation’s team of supply chain, Six Sigma and demand flow experts can help you mitigate your risk of excess inventory in any given product line and manage obsolescence.

More Delivery Flexibility

Creation’s ‘Thinking in Action’ approach to product supply programs will help you conquer your demand variability. Implement a production and delivery strategy that’s optimized specifically for your unique products, geographies and customers.

Creation's Scorecard: Thinking in Action®

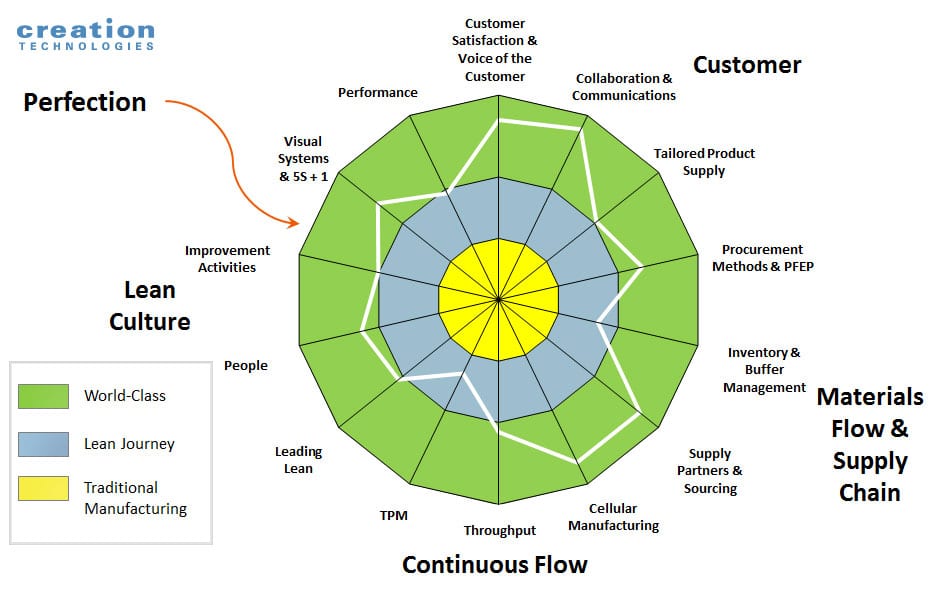

As part of Creation’s Journey, we have developed a unique Scorecard to help us gauge our progress in our Endless Pursuit of Perfection.

Twice a year, our Quality & Lean team in each business unit does an in-depth assessment of many different factors: how we’re serving our customers, materials flow and supply chain, Continuous Flow, etc.

Creation's Proactivity, End-to-End Expertise, Quality, and Six Sigma Knowledge Combine to Deliver Tangible Benefits to OEMs.

Continuous Improvement and Cost Reduction

Like many EMS providers, Continuous Improvement is a philosophy Creation Technologies applies in our production environments through Manufacturing. But it doesn’t stop there.

Creation also has a Supply Chain, a Product Development model, and even some Accounting.

When you partner with Creation, you can be sure we’ll understand your products.

The more you can help us understand your business goals and risks, the more we can help you find new ways to be successful.

- Creation manufacturing business units around the world, including Canada, USA, China and Mexico to optimize your total manufacturing costs

- Tailored Product Supply programs that give you customized delivery models for your products, your market variables, your inventory targets and your customer’s needs

- Dedicated supply chain professionals on your Customer-Focused Team driving procurement and planning improvements, including Plan for Every Part (PFEP)

- Six Sigma Black Belts, Green Belts and Creation’s own Blue Belts leading regular Continuous Improvement activities, and dedicated program management on your Customer-Focused Team driving value-added initiatives in operations and quality

- Dedicated project management on your Customer-Focused Team driving Value and Sustaining Engineering activities, and expert support for engineering change orders (ECOs)

- Access to integrated Creation Design Services team for turnkey product design and re-design

Creation’s electronics manufacturing services go beyond basic assembly and integration to deliver the technical excellence and delivery flexibility that can transform your supply chain.

End-to-End Quality

Quality Results at Any Point in the Product Lifecycle

Creation Technologies produces some of the most complex and technologically advanced products in the world.

Leverage our experience across markets from the high-growth to the highly regulated.

When you work with Creation, you plug in to our high-performance production environment built for cellular and lean manufacturing.

But you can also reap the benefit of working with a full-service provider with specific expertise in Quality and Regulatory Product Design and Development.

Regulatory Expertise for Your Entire Product Lifecycle

- Regulatory and Quality Engineering through Creation Design Services including design validation and verification to help support your redesign where you need external expertise or additional resources

- Prove out your designs with concurrent engineering and rapid prototyping through Creation Express Services

- Manufacturing transfer and NPI at Creation’s production facilities worldwide

- Sustaining engineering through after-market services

Regulatory Expertise

Reduce stress and improve margins. Leverage Creation’s regulatory expertise, experienced and certified people, and company-wide best practices for premium quality.

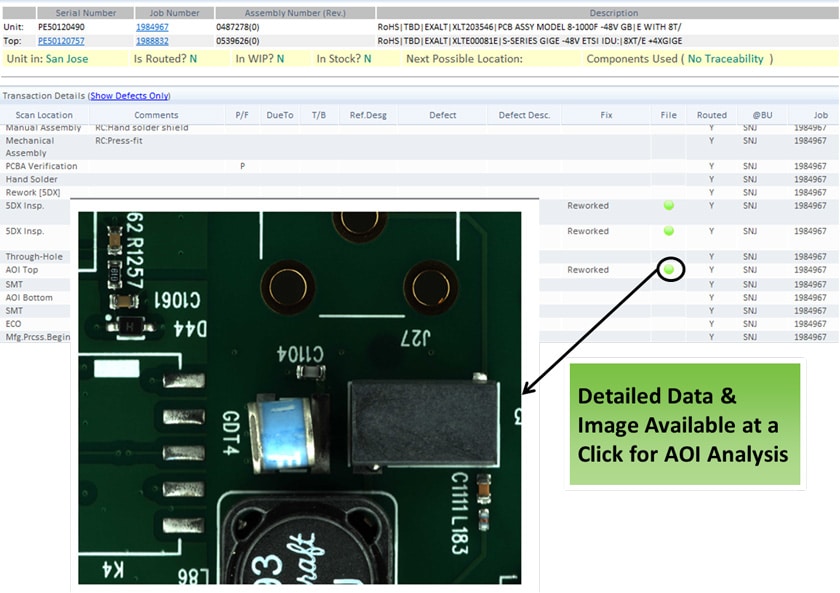

Creation’s Vision Customer Portal provides you with access to detailed quality information and analysis so there’s no second-guessing.

- Standardized procedures, business and quality systems, equipment and training across all Creation business units for your Business Continuity advantage

- Certifications including ISO 9001:2015, ISO 13485:2016, ISO 14001:2015 & AS9100

- Registrations including FDA, UL, CE, CGD, ITAR and C-TPAT

- Vision Customer Portal for real-time supply chain, production and quality data including Test Yields and Trend Analysis, AOI DPMO Trend Analysis and Defect and Rework Data

- RoHS-compliant and lead-free materials handling and processing

Never Settle.

Do you need more reliable materials and suppliers for your products?

Would you like greater efficiencies in process and product design?

How about creative models for procurement and delivery to your customers?

Or a “Right-Shore” global outsourcing strategy that improves your bottom line?

Creation’s Continuous Improvement model will help you maximize your opportunities and protect your investment.